OUR PROFILE

CMR Group is India’s largest producer of Aluminium and Zinc die-casting alloys with a combined annual capacity of over approx 605850 MT. Since its inception, it has maintained its fast-paced growth by leveraging latest technology and continuous improvement.

CMR group commenced its business in 2006, when it put up its first plant in Tatarpur, near New Delhi. The plant deployed sophisticated technologies such as regenerative burner, baghouse, pump furnace and de-coater, rotary sieve, heavy media separation system, induction based sorting system, colur sorting system, eddy current separator, gravimetric separation, shredder, specially designed ladles and auto chargers etc.

CMR Group is presently operating through thirteen manufacturing plants including 5 plants under three Joint Ventures with renowned Japanese companies, Toyota Tsusho Corporation, Nikkei MC Aluminium and Nippon Light Metal Company Limited.

Some of our firsts in India that laid the foundation of our leadership position in the industry are:

- Large-scale Aluminium recycling in a largely unorganized industry

- Highly-automated alloying plant sourced from Europe

- Mechanized sorting facility with eddy current seperators, shredders, spectrometers and gravimetric separation units

- Supply of molten metal to customers from side-by-side plants and also over-the-road

- Recognized as one of the top aluminium billets manufacturers in India

- Has ISO 14001, TS16949,45001 and OHSAS 18001, Research & Development certifications.

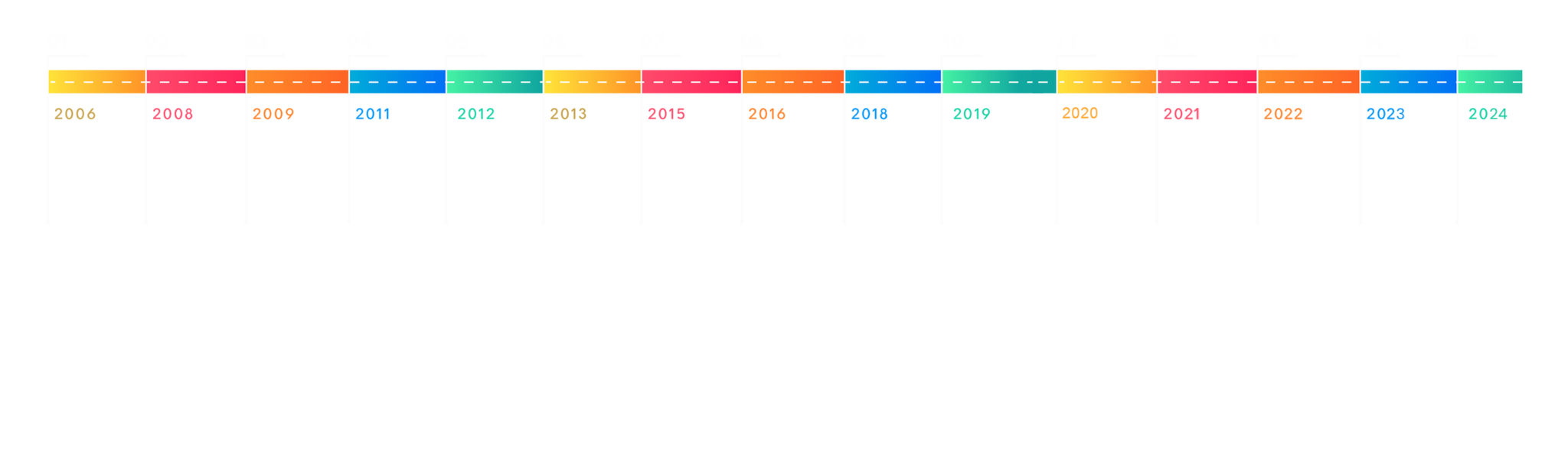

Milestones

17+

17+ 500+

500+ 100+

100+