Aluminium Recycling

Compared with manufacturing through the primary route, recycling of aluminium consumes significantly less power (5-7% of the total energy requirement for primary aluminium). Each tonne of aluminium manufactured through recycling results in saving of 5-6 MT of bauxite, 1-1.5 MT of limestone, 20-25 MT of water and ~14000 kwh of energy (~90-95% of energy savings as per International Aluminium Institute).

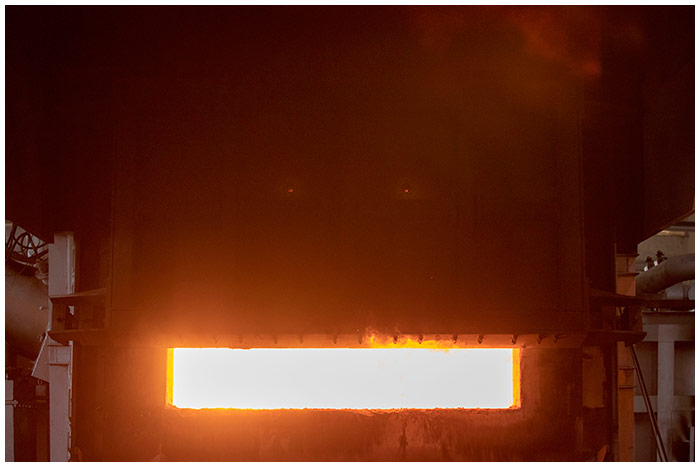

Liquid Metal Supply

CMR Group has made significant investments to introduce liquid metal supply in this industry. This has served as an effective method for emission reduction. Liquid metal supply eliminates the entire process of ingot melting by die-caster, which would otherwise lead to wastage of fuel and loss of metal (melt loss).

Pollution Control Systems

All our plants are equipped with the latest pollution control systems which ensure under 50 mg/Nm3 suspended particulate matter (SPM) from our stacks, Additionally, we continuously endeavour to deploy Energy Saving Technology like Re- generative burners.

Carbon Credits

Our Tapukhera (Bhiwadi) plant has been accredited by the UNFCCC as an environmentally clean plant, eligible for Carbon Credits.